- Published:11 August 2025

When you think about safety on a construction site, the first things that probably spring to mind are hard hats, high-vis vests, and steel-toe boots. But one piece of lifesaving equipment that’s often overlooked is the defibrillator.

In a high-risk environment like a construction site, where workers deal with physical strain, stress, and unpredictable medical emergencies, having a defibrillator on hand could save a life.

In this guide, we take you through everything you need to know about having a defibrillator on a construction site, looking precisely at how defibrillators work, why they’re essential for construction sites, and how to choose the right one for your team.

So, first things first…

What Is a Defibrillator and How Does It Work?

A defibrillator, or AED (Automated External Defibrillator), is a portable medical device that delivers a controlled electric shock to someone experiencing a sudden cardiac arrest.

The device works by analysing the person’s heart rhythm and, if necessary, delivering an electric shock through the chest. This shock is designed to ‘reset’ the heart’s rhythm back to its normal pattern.

AEDs are designed to be simple and safe to use, even by someone with no medical training, because most modern defibrillators will guide the user through the process with clear voice instructions and visual prompts.

Why is it Important to Have Defibrillators on Construction Sites?

It’s pretty fair to say that jobs in the construction industry are among the most physically demanding out there.

Workers often have to face long hours of intense manual labour, typically across a five-day week or more, which naturally puts significant strain on the body, including the heart.

This constant physical exertion can increase the risk of cardiac-related issues, and in some cases, the added pressure on the heart may contribute to a sudden cardiac arrest. Without immediate intervention in the form of CPR and a defibrillator, cardiac arrest is almost always fatal.

Construction sites usually span wide areas of land, so can also be challenging for emergency services to reach quickly. And while the average ambulance response time is around 11 minutes, this can be significantly delayed if the site is in a hard-to-access location.

Unfortunately, every minute counts during a cardiac arrest, and with each minute that passes without treatment, a person’s chance of survival can drop by as much as 10%.

How to Choose the Right Defibrillator for Construction Sites

Not all defibrillators are created equal, so when selecting an AED for your site, there are a few key factors to consider to ensure it’s fit for purpose, easy to use, and ultimately reliable in an emergency.

4 key things to consider when choosing defibrillators for construction sites are:

1. Durability and Weather Resistance

It’s very unlikely that you’ll find a construction site that’s clean or climate-controlled. They’re often exposed to the elements, with dust, dirt, rain, and extreme temperatures being part of daily life. And because of this, any defibrillator used on site must be tough enough to cope with these challenging conditions.

So, when looking around for a defibrillator, we recommend looking for models that are specifically designed for outdoor or industrial use. These units are usually housed in rugged casings made from impact-resistant materials that can withstand being knocked, dropped, or jostled during transport or use.

One of the most useful indicators of durability is the IP rating (Ingress Protection rating), which tells you how well a device is sealed against dust and moisture. For construction sites, an IP55 rating or higher is recommended.

At Defib World, our rugged, site-ready defibrillators empower workers to take immediate action, transforming bystanders into first responders when every second counts.

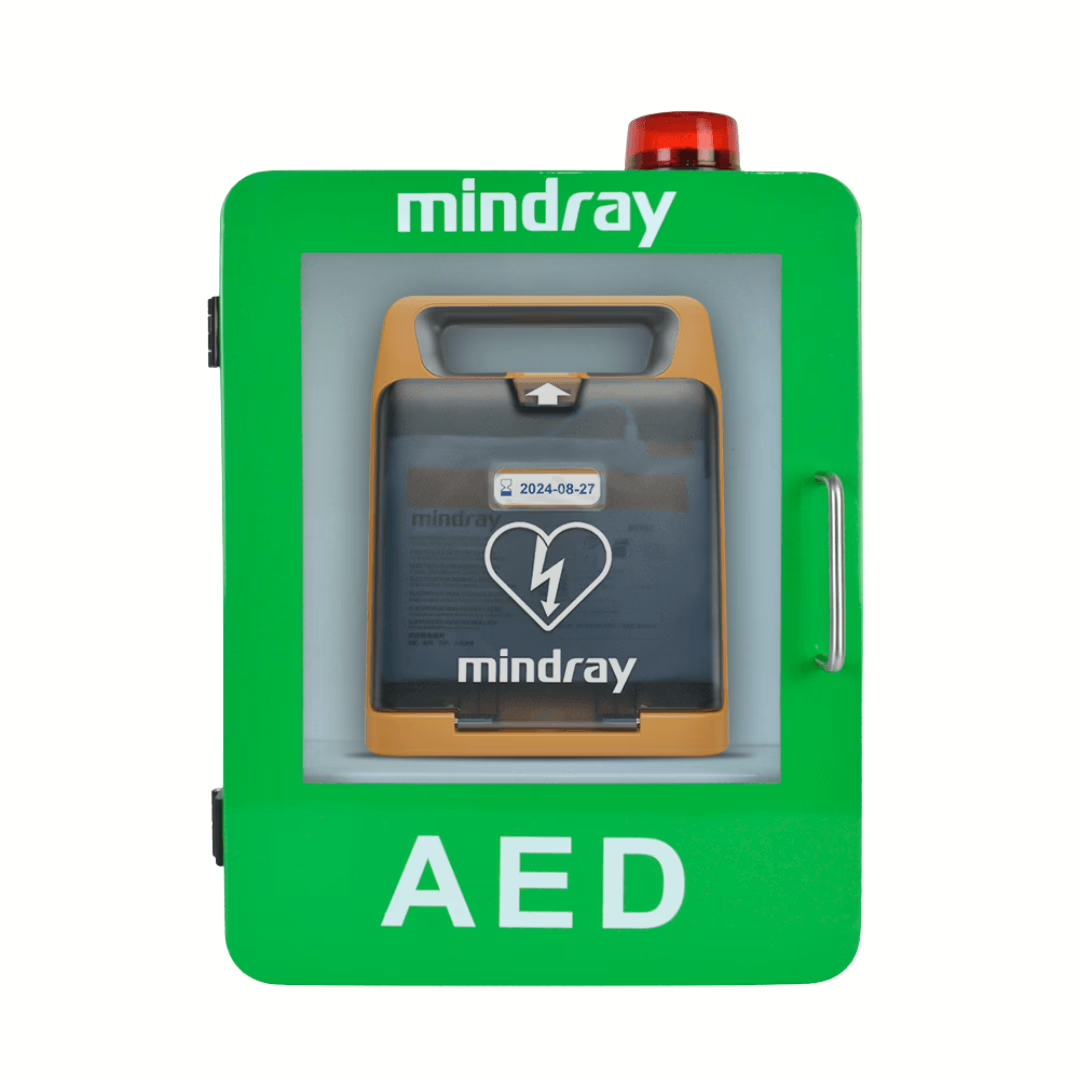

A good example of a quality defibrillator for a construction site is the C1A Mindray Fully Auto AED and DefibCaddy Outdoor Locked Package, which combines a reliable, easy-to-use defibrillator with a weatherproof, secure storage cabinet – ideal for demanding environments.

The C1A unit itself is fully automatic, offers clear voice prompts, and features robust construction with a long battery life, paired with the DefibCaddy Outdoor Cabinet, which is designed to withstand harsh weather and unauthorised access.

2. User-Friendliness

As we touched on above, every second counts, and the last thing anyone needs is a complicated device, which is why user-friendliness is one of the most important factors when choosing a defibrillator for a construction site.

In the UK alone, there are around 30,000 out-of-hospital cardiac arrests every year, of which 80% occur at home, and the remaining 20% occur in a public place. The reality is therefore that the first person to respond to a cardiac arrest may not be a trained first aider, so the defibrillator must be intuitive enough for anyone to use confidently and effectively.

Modern AEDs are designed to guide the user through the entire process, step by step. You want to look for a model that offers loud, clear voice instructions, which is especially important for noisy environments like construction sites.

3. Semi-Automatic vs. Fully Automatic

When choosing a defibrillator for your construction site, one of the key decisions is whether to go for a semi-automatic or fully automatic model, which, as you can probably tell by the name, function slightly differently in how the shock is delivered.

Semi-automatic defibrillators will guide the user through the rescue process, analysing the casualty’s heart rhythm just like a fully automatic unit. That said, if a shock is needed, the device will prompt the responder to press a button to deliver it.

Fully automatic defibrillators on the other hand, take it one step further. Once the pads are attached and the heart rhythm is analysed, the device will deliver the shock automatically if it determines one is necessary. It will often give you a countdown and a verbal warning so bystanders can move away safely.

You can shop our wide range of semi-automatic and fully-automatic defibrillators here at Defib World. But if you’re not too sure which type is best for your environment, feel free to give our experts a call on 0330 223 6336 – we’d love to help you.

Whether you select a fully automatic or semi-automatic AED, the ultimate goal is the same – delivering a lifesaving shock in the shortest possible time.

4. Portability and Mounting Options

Construction workers may need to carry the defibrillator across uneven ground, between different site zones, or even to remote locations within the site. For this reason, the AED should be lightweight and come with a convenient carrying case or handle for easy transport.

As well as portability, defibrillators also need a fixed, visible, and secure location when not in use, which is why having a designated mounting spot, such as a wall-mounted cabinet, ensures everyone on site knows exactly where to find the AED in an emergency.

Our outdoor defibrillator cabinets at Defib World are designed to be weatherproof and robust, offering protection against rain, extreme temperatures, and even vandalism. Some cabinets also come with heating elements to prevent the defibrillator from freezing in colder climates, maintaining optimal operational temperature.

There we have it! We hope this blog has taught you everything you need to know about defibrillators for construction sites.

If you’re considering a defibrillator, have a look through our range of easy-to-use defibrillators for construction sites and check out our regularly updated blog to learn more about CPR and first aid.

And of course, if you need assistance or have any questions at all, please call us on 0330 223 6336 or drop us an email at sales@defibworld.org.

.jpg)